We are also the reference manufacturer in the market for static mass properties measurement systems, aeronautical balance measurement and centre of gravity measurement. From small parts to large aircraft or complete satellites.

Systratec shares with its customers and suppliers a boundless passion for innovation, a passion we apply to all our designs, creating electronic instrumentation of the highest quality and accuracy in the industry.

Our weighing and mass distribution measurement systems are aimed at the aerospace, aeronautical and automotive industries, logistics companies, all industrial companies, governments and many other sectors of activity, prioritising durability and measurement quality over all other considerations.

CUSTOMERS WHO TRUST SYSTRATEC

High-End Weighing

High-End Static and dynamic wheel or axle weighing and center of gravity measurement for transport and competition vehicles, ISO containers and for any industrial process.

Centre of Gravity in the laboratory

Measurement of mass distribution in small parts and assemblies, nanosatellites, microsatellites and avionics.

Aircraft and Helicopters

Industrial systems for aeronautical weight and balance measuring. Portable platforms, embedded systems and on-jack weighing.

Custom Instrumentation

WHAT MAKES US DIFFERENT?

The desire to surpass traditional weighing technologies, building the most advanced, accurate and longest-lasting weighing systems on the market, is what drives the entire SYSTRATEC team. This ambitious objective is achieved by working on each scale in depth, seeking excellence in all the technologies used: the structural design, the choice of materials, the sensors used, the hardware of the measurement electronics and weight displays, the firmware of all the electronics, the calibration procedures and tools and countless other details. It is by taking the utmost care with each instrument, load receptor and electronics that we can guarantee our customers that the investment they have made in the purchase of their measuring equipment is protected and profitable by having an instrument that can be upgraded for many years and that is always capable of providing the highest quality of measured value in the industry. SYSTRATEC weighing and centre of gravity measurement systems incorporate the following unique technologies:

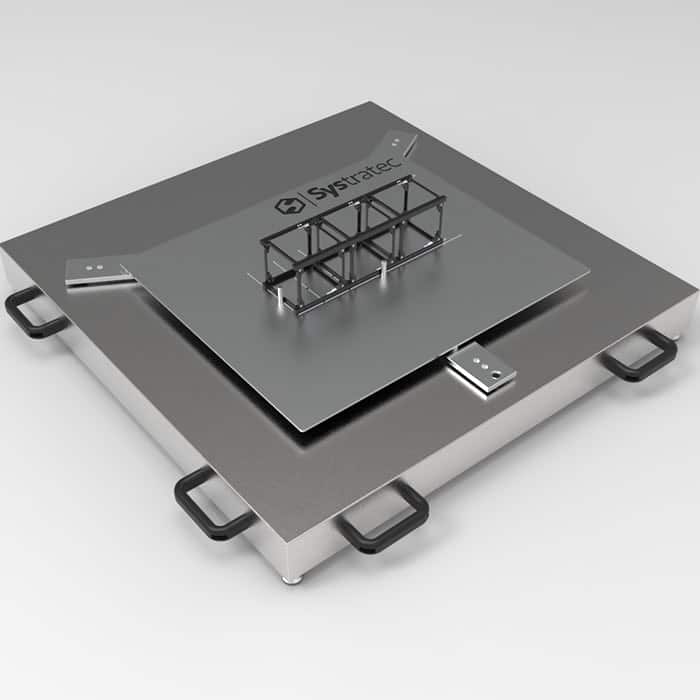

ULTRA-RIGID STRUCTURES

We build our scales and all our load receptors using only aerospace grade aluminium, stainless steel and carbon fibre. Our structures are designed to have zero deflection at nominal load over the tyre footprint. This results in greater linearity, accuracy and durability of all our instruments compared to traditional solutions.

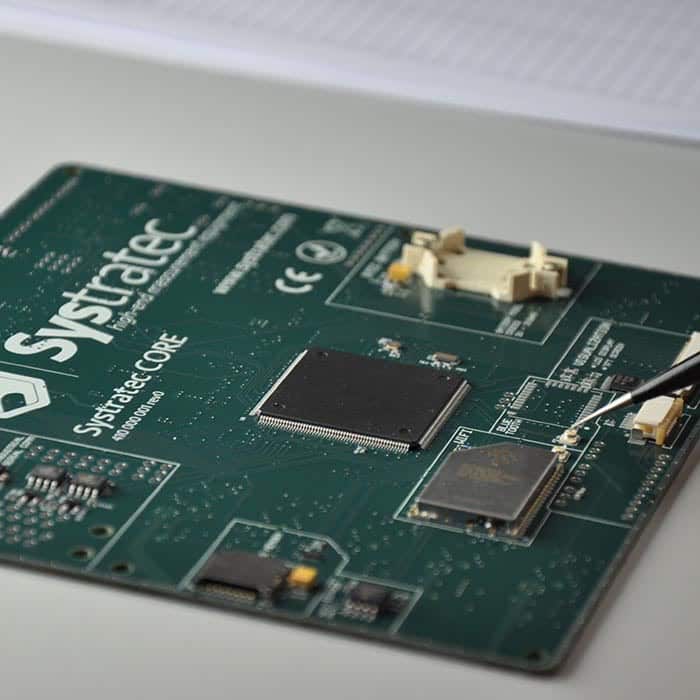

FULL FIRMWARE CONTROL

As manufacturers of our own electronics, we have full control over the internal firmware. This allows us to offer the market

a very high capacity of adaptation and integration of our instruments in any customer’s process. It also allows us to update our instruments throughout their useful life, evolving their capabilities as our customers’ needs evolve.

MEASUREMENT OF THE POSITION OF THE LOAD

Our most advanced scales provide, in addition to the weight value, the exact position of the load on the platform with millimetre accuracy. This unique feature greatly reduces uncertainty in static mass distribution, centre of gravity or aircraft centring calculations.

HIGH-END WEIGHT SENSORS

We build our scales and load cells around high-end stainless steel sensors based exclusively on strain gauges. Partners since 2015 with the German sensor manufacturer HBM® Hottinger Brüel Kjaer, we exclusively use these load cells for their outstanding metrological quality and durability, which are recognised worldwide and present in all reference laboratories. The use of these high-end load cells allows for greater ease of adjustment year after year, virtually indefinitely, compared to other technologies such as piezoelectric, capacitive, or hydraulic pressure sensors, or low-quality load cells, which lose their ability to adjust after only a few years of use.

INDEPENDENT OPERATION OF EACH SENSOR

We do not use summing boxes in our instruments. Our proprietary electronics are capable of acquiring the individual signals of up to 20 load cells in parallel and simultaneously. We monitor each sensor during the weighing process to ensure we always provide the best possible measurement, detecting saturation, short circuits, unwanted traction states and other potential problems before giving a weight value that may not be of our trademark quality.

GREATER PRECISION

LONGER SERVICE LIFE

GUARANTEE 2 YEARS

IMPROVED USABILITY

LESS MAINTENANCE

UPGRADEABLE FIRMWARE

BETTER INTEGRATION

Featured Product

axle|MOBILE

The portable system for static and dynamic axle weighing of road vehicles.

Featured Product

Auto|WS

A new Reference among portable systems for weighing and measuring the centre of gravity in cars and light aircraft.

Featured Product

CARBON|aero Reference

The most advanced Weighing and Gravity Center Measurement Mobile System for the Aircraft Industry